Products

Our range of Swedish powdered Damascus steels is suitable for all types of knives, tools and art. Every piece of steel undergoes rigorous inspection to ensure excellent quality.

For more styles, please download our PDF document:Damascus steel style introduction

Martensitic Swedish Powder Damascus Steel(DS93X™)

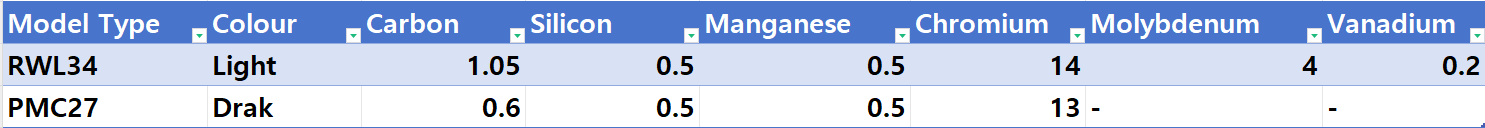

The martensitic Swedish powder - made Damascus stainless steel of Damasteel Company is a product of powder metallurgy. There are two alloys, RWL34 and PMC27. They both belong to variants of 420 martensitic stainless steel, and their chromium content is not less than 13%. These alloys are widely used in situations where one or more of the following characteristics are required:

It has high hardness after heat treatment.

It has strong corrosion resistance.

It is easy to grind and polish.

It has high purity and cleanliness.

Each alloy combines corrosion resistance and hardenability well. The combination of these two properties is one of the reasons why this product is particularly suitable for use as a knife material. Examples of other applications include tableware, jewelry and other products that require both corrosion resistance and hardness.

Figure 1: The table shows the weight percentages of the nominal chemical components in the constituent alloys.

Mechanical and physical properties

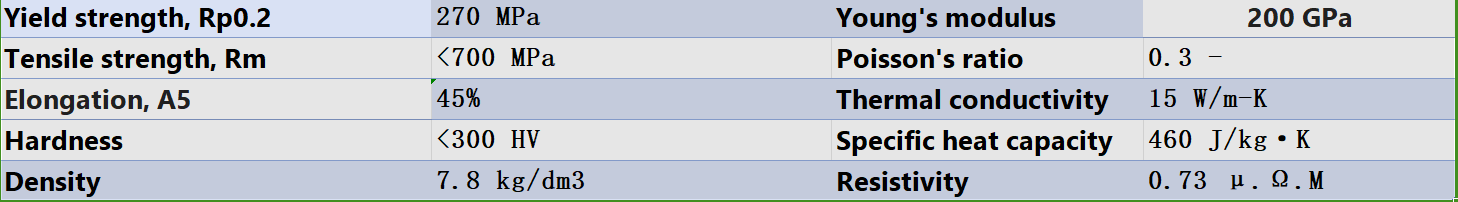

Mechanical and physical properties of annealed DS93X (bars and plates), minimum values at 20 °C.

Figure 2: The table shows the mechanical and physical properties of Damasteel martensitic stainless steel (DS93XI) in the annealed state.

Corrosion Resistance

Martensitic stainless steel has moderate to good corrosion resistance, so it has a wide range of applications. We added molybdenum to RWL34. As a result, our Swedish powder Damascus steel has higher corrosion resistance than ordinary martensitic stainless steel.

Hot Working

The hot working temperature is 1050 - 1160 °C (1920 - 2120 °F).

Compared with low-alloy steel, martensitic stainless steel has a stronger deformation resistance, almost doubling. Therefore, there is relatively little space for hand forging. Melting begins at 1220 °C (2230 °F), which means that this material is very sensitive to overheating. See Figure 1. The temperature needs to be well controlled. Electric furnaces or gas furnaces are recommended.

After hot working is completed, slow cooling is recommended because there is a risk of cracking when the material transforms into martensite at about 200 °C (390 °F). Vermiculite or other thermal insulation materials are recommended.

Overheated material with typical cracks from edge to center (as shown in the picture above).

Damasteel creates all possibilities.

Style introduction

Swedish powdered Damascus steel is widely used in knives and crafts due to its unique pattern and strength. Here are the current styles:

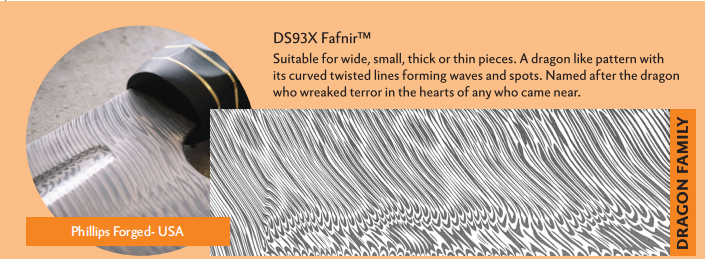

1. DS93X Fafnir™

Suitable for wide, small, thick or thin pieces. A dragon like pattern with its curved twisted lines forming waves and spots. Named after the dragon who wreaked terror in the hearts of any who came near.

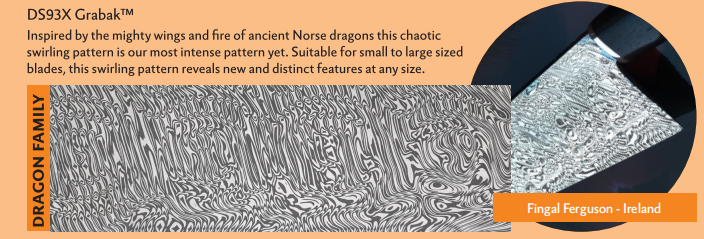

2. DS93X Grabak™

Inspired by the mighty wings and fre of ancient Norse dragons this chaotic swirling pattern is our most intense pattern yet, Suitable for small to large sized blades, this swirling pattern reveals new and distinct features at any size.

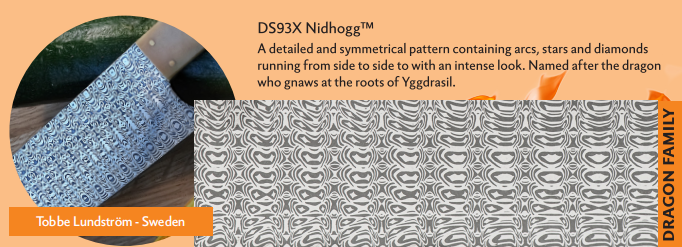

3. DS93X Nidhogg™

A detailed and symmetrical pattern containing arcs, stars and diamonds running from side to side to with an intense look. Named after the dragon who gnaws at the roots of Yggdrasil.

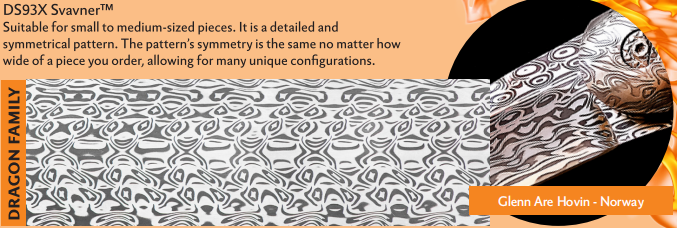

4. DS93X Svavner™

Suitable for small to medium-sized pieces, lt is a detailed and symmetrical pattern,The pattern's symmetry is the same no matter how wide of a piece you order, allowing for many unique conhgurations.

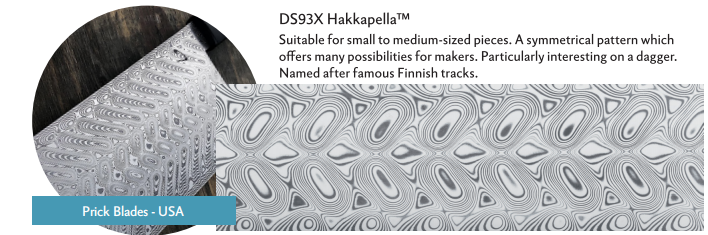

5. DS93X Hakkapella™

Suitable for small to medium-sized pieces.A symmetrical pattern which ofers many possibilities for makers. Particularly interesting on a dagger. Named after famous Finnish tracks.

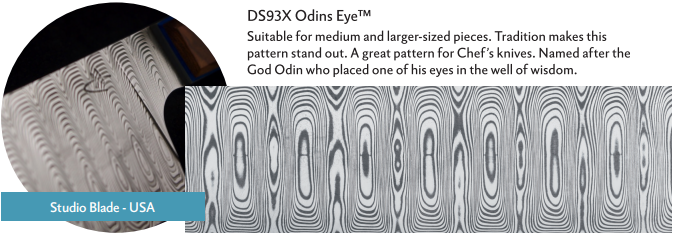

6. DS93X Odins Eye™

Suitable for medium and larger-sized pieces. Tradition makes this pattern stand out. A great pattern for Chef's knives. Named after the God Odin who placed one of his eyes in the well of wisdom.

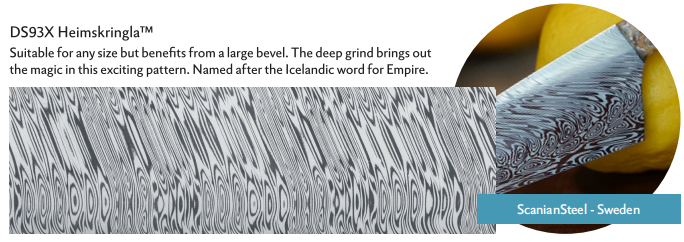

7. DS93X Heimskringla™

Suitable for any size but benefts from a large bevel. The deep grind brings out the magic in this exciting pattern. Named after the lcelandic word for Empire.

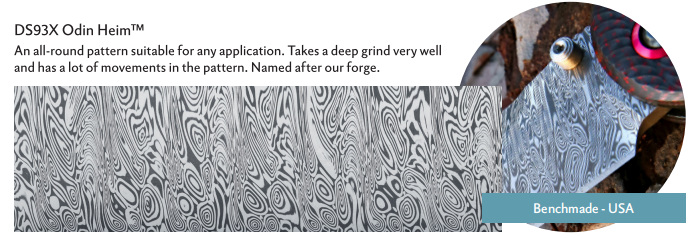

8. DS93X Odin Heim™

An all-round pattern suitable for any application. Takes a deep grind very well and has a lot of movements in the pattern. Named after our forge.

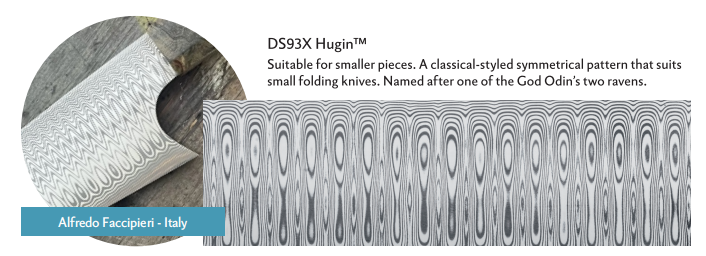

9. DS93X Hugin™

Suitable for smaller pieces. A classical-styled symmetrical pattern that suits small folding knives. Named after one of the God Odin's two ravens.

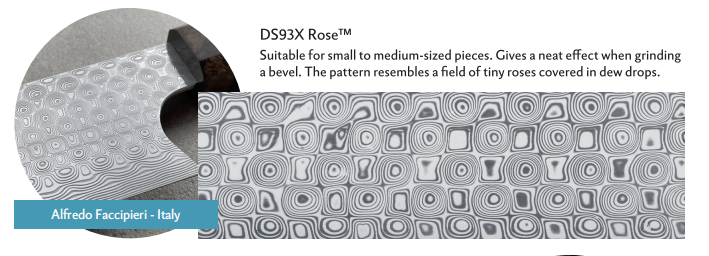

10. DS93X Rose™

Suitable for small to medium-sized pieces. Gives a neat effect when grinding a bevel. The pattern resembles a feld of tiny roses covered in dew drops.

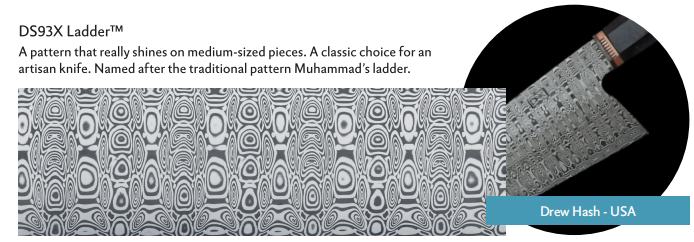

11. DS93X Ladder™

A pattern that really shines on medium-sized pieces. A classic choice for an artisan knife. Named after the traditional pattern Muhammad's ladder.

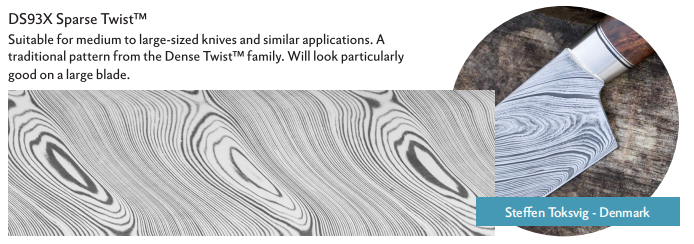

12. DS93X Sparse Twist™

Suitable for medium to large-sized knives and similar applications. A traditional pattern from the Dense Twistrm family. Will look particularly good on a large blade.

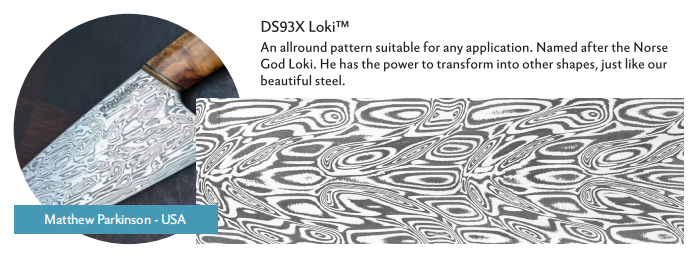

13. DS93X Loki™

An allround pattern suitable for any application. Named after the Norse God Loki. He has the power to transform into other shapes, just like our beautiful steel.

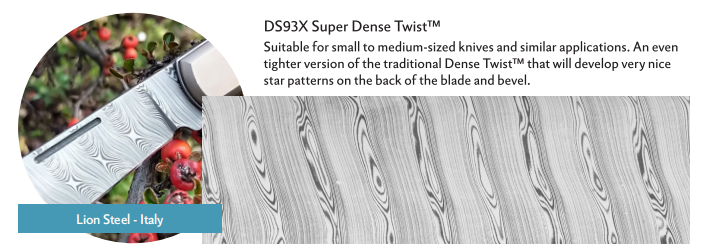

14. DS93X Super Dense Twist™

Suitable for small to medium-sized knives and similar applications. An even tighter version of the traditional Dense Twist™ that will develop very nice star patterns on the back of the blade and bevel.

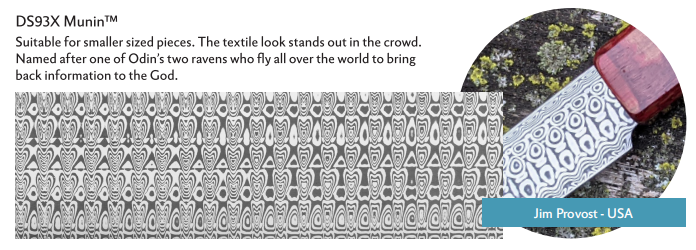

15. DS93X Munin™

Suitable for smaller sized pieces. The textile look stands out in the crowd. Named after one of Odin's two ravens who fy all over the world to bring back information to the God.

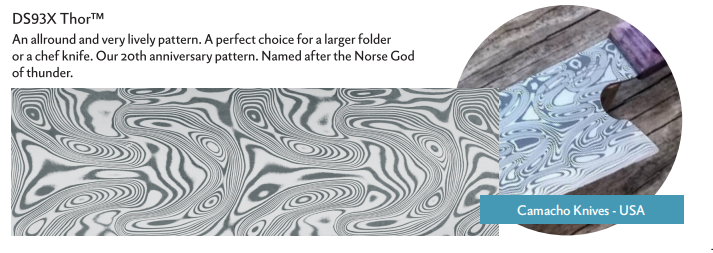

16. DS93X Thor™

An allround and very lively pattern. A perfect choice for a larger folder or a chef knife. Our 2oth anniversary pattern. Named after the Norse God of thunder.

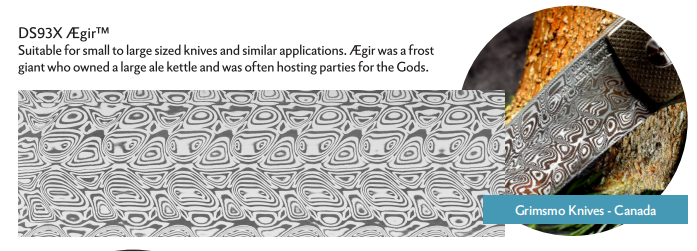

17. DS93X /Egir™

Suitable for small to large sized knives and similar applications. /Egir was a frost giant who owned a large ale kettle and was often hosting parties for the Gods.

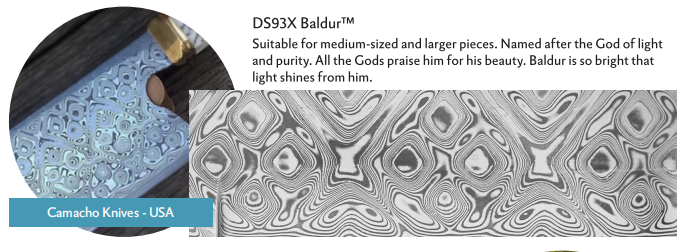

18. DS93X Baldur™

Suitable for medium-sized and larger pieces. Named after the God of light and purity. All the Gods praise him for his beauty. Baldur is so bright that light shines from him.

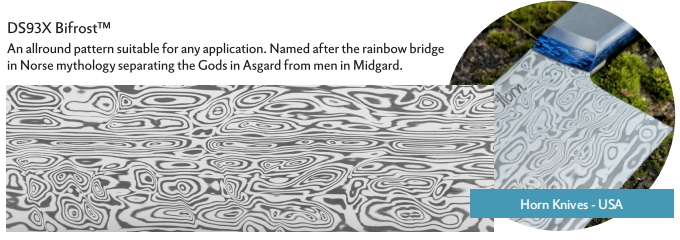

19. DS93X Bifrost™

An allround pattern suitable for any application. Named after the rainbow bridge in Norse mythology separating the Gods in Asgard from men in Midgard.

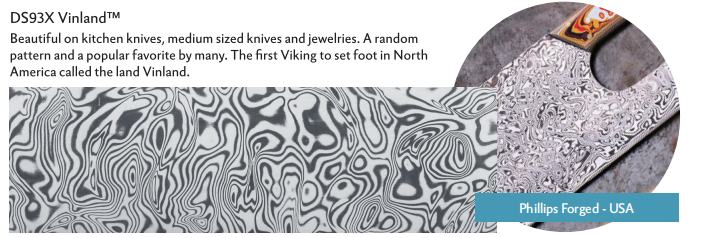

20. DS93X Vinland™

Beautiful on kitchen knives, medium sized knives and jewelries.A random pattern and a popular favorite by many. The frst Viking to set foot in North America called the land Vinland.

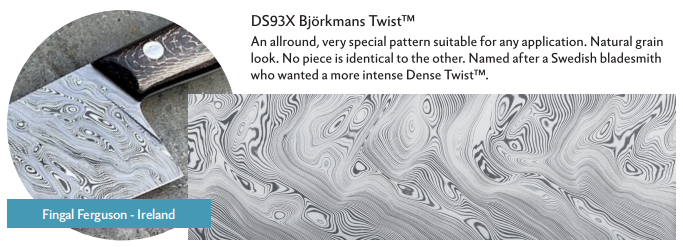

21. DS93X Björkmans Twist™

An allround, very special pattern suitable for any application. Natural grain look. No piece is identical to the other. Named after a Swedish bladesmith who wanted a more intense Dense Twist™.

22. DS93X Dense Twist™

Suitable for any application. Will develop a very nice star pattern on the back of the blade and bevel. Comes with a proud heritage for barrel making.

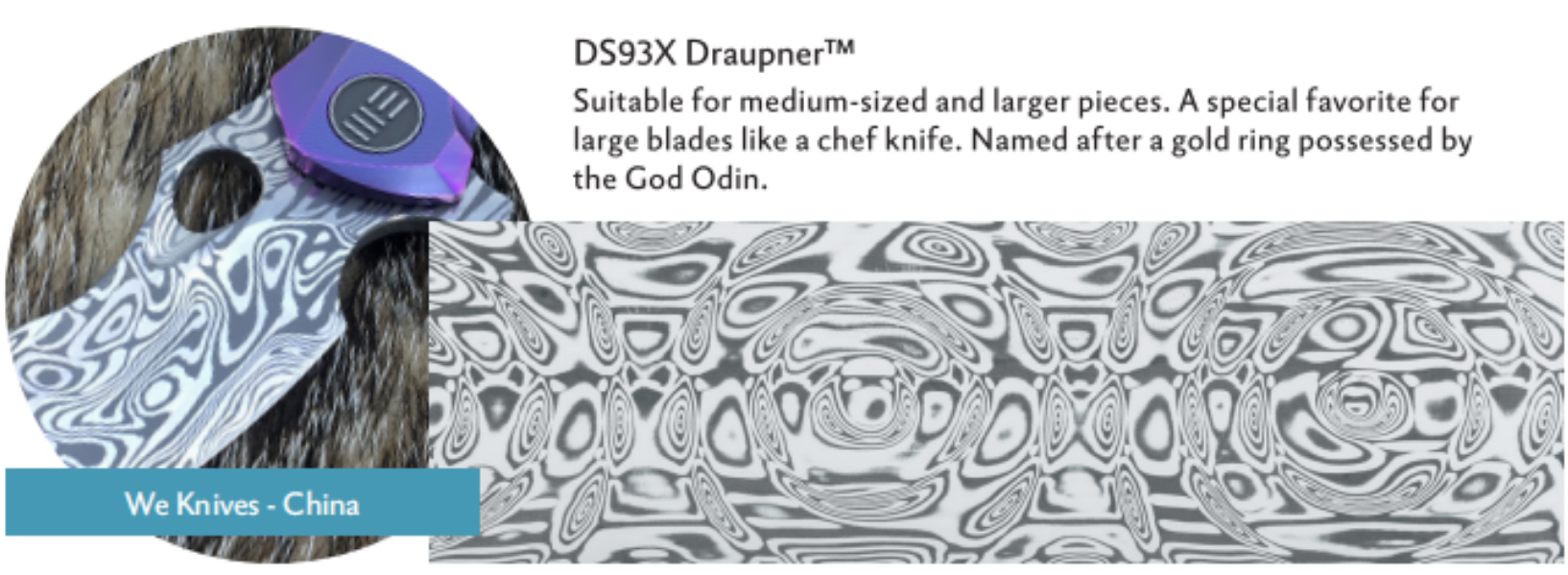

23. DS93X Draupner™

Suitable for medium-sized and larger pieces. A special favorite for large blades like a chef knife, Named after a gold ring possessed by the God Odin.

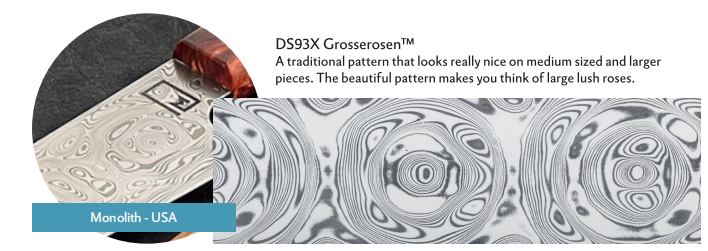

24. DS93X Grosserosen™

A traditional pattern that looks really nice on medium sized and larger pieces.The beautiful pattern makes you think of large lush roses.

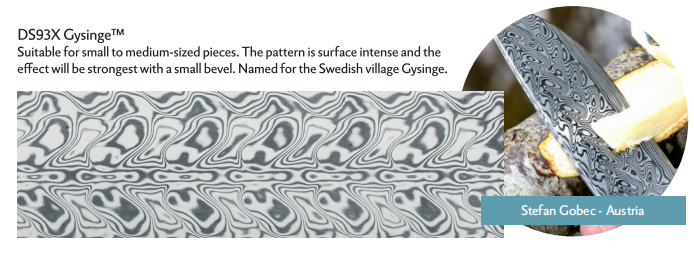

25. DS93X Gysinge™

Suitable for small to medium-sized pieces. The pattern is surface intense and theeffect will be strongest with a small bevel. Named for the Swedish village Gysinge.

Why choose Damasteel?

Damasteel@ is the best performing stainless Damascus patterned steel in the world using the latest gas-atomized PM technology with very high cleanliness. lt has incomparable toughness and strength combined with excellent edge retention and corrosion resistance.

For more style information, please continue to pay attention to our website.

Technical Knowledge

Heat Treatment(DS93X™)

Due to the risk of cracking, the materials should be annealed after hot working before grinding, cutting and machining. It is recommended to fully transform the materials by annealing, that is, at 900 °C (1650F) for one hour, then cooling to 750 °C (1380F) in one hour, and finally maintaining at 750 °C for four hours. All martensitic materials supplied by Damasteel are soft - annealed to 230 - 280 HV (20 - 28 HRC).

Hardening(DS93X™)

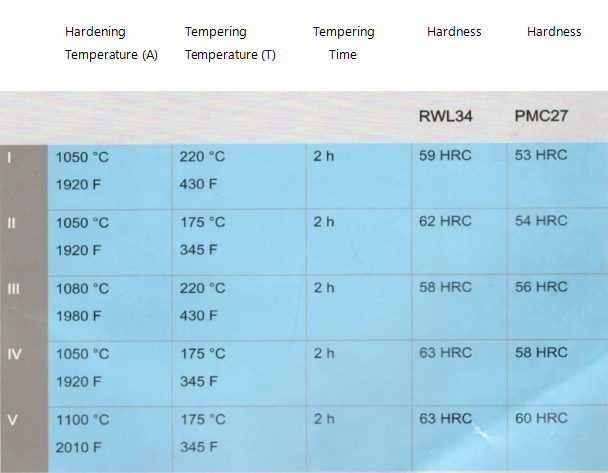

For 3.2 - mm steel sheets used for knives, the following heat treatments are recommended.

This table presents the recommended hardening and tempering temperatures for 3.2 - mm steel sheets of the corresponding alloy hardness.

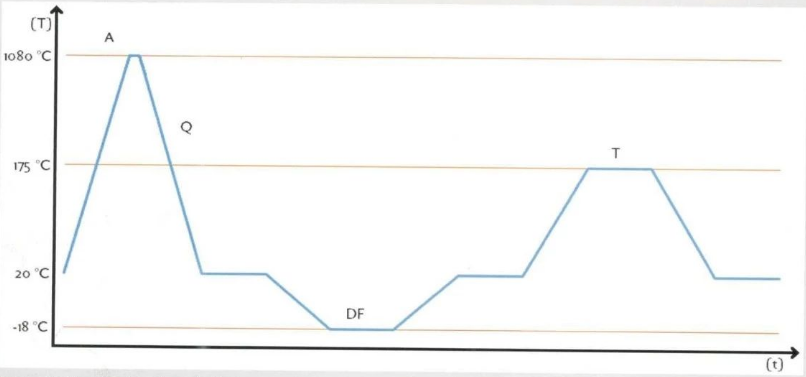

The recommended heat - treatment processes IV and V include deep - freezing treatment (DF) at - 80 °C (- 110F). To ensure optimal corrosion resistance, we recommend using a lower tempering temperature. The following time - temperature curves are available for reference, as shown in the figure below.

The schematic curves of hardening and tempering temperatures are shown in the figure.

A

Austenitizing. Process the 3.2 - millimeter steel sheets for 8 minutes. For every half - millimeter increase or decrease in thickness, the processing time should be increased or decreased by one minute accordingly.

Q

Cool rapidly to room temperature. We recommend using quenching oil to reduce the temperature to room temperature within two minutes. If cooled in air, pressure should be applied to the steel piece to avoid deformation caused by uneven cooling.

DF

Although deep - cooling is not essential, it can enable the complete transformation of martensite and increase hardness. The processing time is about one and a half hours.

T

Tempering. The processing time is two hours.

Cold Working

Cold working of martensitic stainless steel is not as easy as that of traditional austenitic stainless steel, but it can be formed and processed through various cold - working operations. It has good ductility, and any cold treatment will increase the strength and hardness of the material.

Welding

Martensitic stainless steel will undergo martensitic transformation and lead to cracking when cooled to 200 °C after any hot working. To avoid this situation, the steel parts can be pre - heated or post - weld heat - treated. Our Damascus steel can be welded by all traditional welding methods.

Mechanical Processing

Compared with traditional austenitic stainless steel, martensitic steel has some specific machining properties. Martensitic stainless steel is usually easier to machine than other types of stainless steel. The machining characteristics of our Swedish powder Damascus steel are as follows:

· Low tensile strength but high work - hardening degree.

· There is a tendency of built - up edge on the cutting edge.

· Avoid the appearance of hard and continuous chips by using chip - curling tools.

Grinding and Polishing

The common grinding and polishing procedures for austenitic stainless steel are also applicable to martensitic stainless steel.

Grinding wheel recommendation:

Silicon carbide, grit size 46, soft, open - structured, ceramic - bonded (C46J6V)

· Speed: 35 meters per second

· Feed: 0.01 - 0.05 millimeters per stroke

The speed of the workpiece can be 1/60 of the grinding speed.

Hardening And Etching Treatment

1.Grind to the desired shape with 60 - and 120 - grit abrasives.

2.Harden according to the guidelines on the previous page.

3.Polish with a fine - grained roller and wax.

4.Operate according to the etching guidelines on the next page.

5.Wash the workpiece in water.

6.Grind the blade edge if you are making a knife.

Acid Pickling

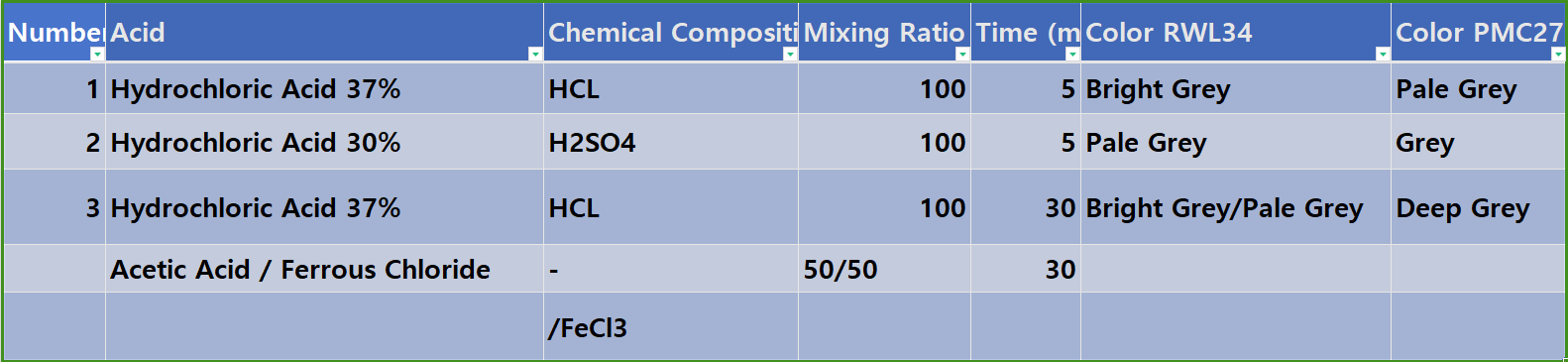

In order to bring out the texture of our steel, pickling must be carried out. Different acids and mixtures of acids can be used according to different effect requirements. Several suggestions are given in the table below.

Polish the steel piece and degrease it carefully. Finally, apply oil - free acetone.

Prepare the pickling solution in the following proportions, and always remember to add acid to water.

The above table shows the pickling suggestions for the corresponding colors and reliefs of different alloys.

Acid - vapor is harmful. Handle with care.

1.Formula 3 (In table) is a high - contrast pickling process that requires two steps. First, pickle with hydrochloric acid for 30 minutes, and then immediately place it in a mixture of ferrous chloride and vinegar for pickling for another 30 minutes.

2.Place the steel piece into the mixture and leave it for a period of time as required. The time suggestions on the previous page can bring about appropriate results

3.Neutralize the steel piece, for example, by putting it into a bicarbonate solution.

4.Wash it clean in water.

5.Formula 3 requires a little grinding with a high - grit sanding belt.

6.If necessary, carefully polish the surface until the top is shiny. If you over - polish, the texture will disappear and you'll have to start all over again.

7.Clean the residual polishing paste on the steel piece.

8.If you are making a knife, do the final grinding of the blade at this time.

The purpose of pickling is to reveal the texture on the finished product. The optimal etching state is achieved by carefully polishing and meticulously degreasing the surface. It is best to immerse the workpiece in the pickling solution. After pickling, the steel piece should be thoroughly washed in water. Finally, use a brush and soap to clean, which can remove the remaining acid solution.

The above are the detailed operation details of heat treatment & pickling.

Understanding the production process of Damascus steel, the advantages of powder metallurgy, and the care and maintenance guidelines can enhance your understanding of our products.

Damasteel Customer

Some of Damasteel Customers:

Clicking the icon can lead to the relevant webpage.

Notification Policy

The information provided on this website may be changed without notice. We have made every effort to ensure the accuracy of the content, but Damasteel and its affiliated companies are not responsible for any misleading errors that may exist in the information. The suggestions and descriptions of the final use and processing methods of products are for reference only, and Damasteel and its affiliated companies are not responsible for the consequences arising therefrom. Customers should be aware of the scope of application before using the products provided or produced on this website.

Contact Information

If you have any questions or need more information, please contact us in the following ways.

Email: zenithtoplife@gmail.com

FaceBook: https://www.facebook.com/share/ZBo2bXb1eqoRxEkv/?mibextid=LQQJ4d